Add to Cart

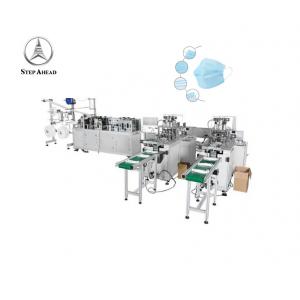

Ultrasonic Welding 220VAC Surgical Mask Making Machine

Product description

Introduction of full automatic face mask machine

This production line is a fully automatic 1+2 mask machine, one mask main body machine drives two ear loop welding machines.

This machine adopts PLC, touch screen control, main conveyor belt adopts servo transmission motor, accurate transmission, stable control, adjustable output speed

After the mask main body is output by the machine, the mask body piece is transferred to the turning mechanism by the conveyor belt structure. Body mask via flip agencies will face mask to connection machine conveyor belt, again through the conveyor belt will mask the body mask piece to the front of the machine above the first mask plate, finally through the cylinder down the mask onto mask ear loop welding machine position, follow-up by ear loop welding of the mask to add ear rope of mask, then mask is complete.

Specification

| Product name | High-Speed Mask making machine |

| Power supply | 220VAC±5 50HZ 9kw |

| Production speed | 6000-9000pcs/hour |

| Mask Size | 17.5*9.5cm |

| Environmental requirements | 10-35 ℃, general dust-free workshop |

| Air source | 0.5~0.7 MPa, 300L/min |

| Dimension | 6500mm(L)×4500mm(W)×1900mm(H) |

| Weight | <2500kg |

| Certification | CE |

| Pass rate | >98% |

| Warranty | 1 year |

| Humidity | 0-95% non-air conditioner |

| Logo | Customized mask logo available |

Advantages:

The whole machine adopts the aluminum alloy structure, which is more beautiful and sturdy.

High stability, with about 98% Product Qualification Ratio.

High-speed output lines, high output.

Fully automatic outer earloop spot welding machine colleagues make the mask sheet and the external ear spot welding part, it can save labor, once the non-woven fabric raw material is run out, the machine will stop automatically.

Using high-quality components like servo motor, ultrasonic, PLC system,led control panel, etc. In the mask production line, to ensure the machine can last longer.

Test run a 24-hours working performance test, to ensure the machine’s stability before the final delivery.

Why choose us?

• Provide one-stop solutions from raw material to the final product

• One-to-one technical support

• 24-hour online support, 8 hours problem solving

• Certificated supplier

• Professional development team

• Over 10-years profound experience on the automatic equipment industry

• Export standard

• Reasonable price

• Timely delivery

• Superior quality

• Good service

Product details

Product Packing

FQA

Q: Can you send a catalog?

A: Yes,we do provide a catalog. Don't hesitate to contact us to ask us to send you one.

Q: When and how can I get the tracking number?

A: As one as we make the shipping, I will tell you the tracking number. If you want to know something about the goods on the way, I will please to help you.

Q: You are a factory or trading company?

A: We are a manufactory and trading company, we are the direct seller, so we can give you the best price and service.

Q: Where are you located?

A: Our factory is located in Shenzhen, Guangdong.